Product Description

Product Description

TRUCK TENSIONER for CHINAMFG ENGINE CHINAMFG ENGINE CHINAMFG CHINAMFG MAN ENGINE CHINAMFG ENGINE WP4 P10H

PART NUMBER:’61263 M61QB-815710 E21 M6 MS40D-1057150 W31 LMEMA-1057150 J63YF-1057150 G3RYA-1057150 FW5 SSF1 S51 G2HQP-1057160 J63YF-1057160 G5AYA-1057160 G5AYS-1057160 L52QA-1057160 186~/0 J4208-10571 MS40D-1057160 6112-150 J571A-1057160 D L3EL1-1057161 KA J62YS-1057150 D557155571 DD3936213 3937553 3937555 3976834 3914086 39229-0 8-97161198-1 A47

We can supply all kinds of CUMINS ENGINE XICHAI engine parts,MAN engine parts and CHINAMFG WP7 WP4 WP10 WP12 P10H engine parts,such as liner kit,crankshaft,cylinder block,starter,alternator,flywheel,filters,cylinder head,gear pump,oil pump and so on.If you demand or are interested in our products,please contact with me for details.Look CHINAMFG to your inquiry anytime.

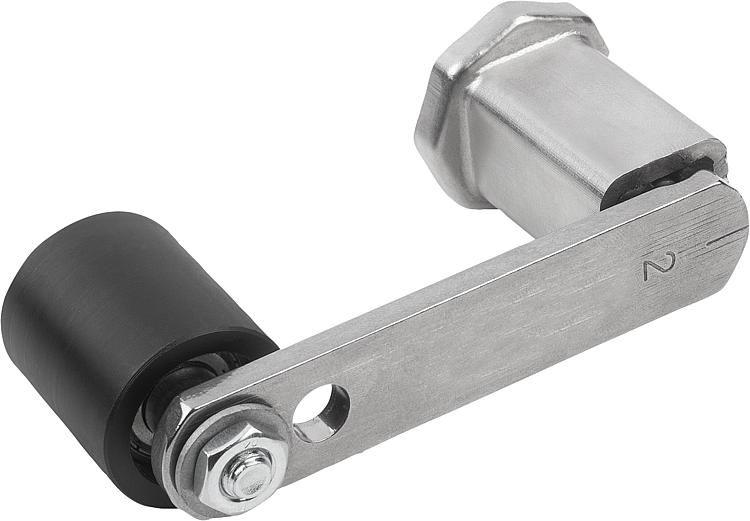

Detailed Photos

Packaging & Shipping

1. Packaging details: carton and wooden box packaging,woven bag,brown box, or

according to customer requirements.

2. Delivery Period: 7-30 working days after

receiving 30% deposit byTT

3. Port: HangZhou Port,China.

4. Transport: By sea, by

air,DHL,FEDEX,UPS,TNT,

FAQ

1.Q:About the payment term.

A: We can accept TT,LC,PAYPAL,WESTERNUION,and so on

2.Q:About the Quality and price

A: We supply good quality products to all our customers,give the competitive price.

3.Q:About the warranty period

A:At least half year, some parts are even longer.

4. Q:How to make order ?

A:Customer can contact us online,or send email with detail inquiry list,then we can reply soon

5.Q:About the discount

A:If the quantity large,we will give resonalbe discount.And for long time cooperation customer,we can give credit support

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Change for Quality Problem |

|---|---|

| Warranty: | Half Year |

| Car Make: | Sinotruk HOWO Shacman FAW Beiben |

| Engine Type: | Weichai Engine P10h |

| Quality: | Good Quality |

| Application: | Sinotruk HOWO FAW Shacman Beiben |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

What advantages do tension pulleys offer in material handling and conveyor systems?

Tension pulleys offer several advantages in material handling and conveyor systems, contributing to efficient and reliable operation. Here’s a detailed explanation of the advantages provided by tension pulleys in these systems:

1. Proper Belt Tension: Tension pulleys ensure the proper tension in conveyor belts used in material handling systems. Maintaining optimal tension is crucial for smooth and efficient belt operation. Tension pulleys help prevent belt sagging or excessive slack, ensuring consistent contact between the belt and pulleys, and maximizing the grip and power transfer. Proper belt tension minimizes slippage, enhances belt life, and reduces the risk of jams or disruptions in material flow.

2. Belt Tracking: Tension pulleys assist in maintaining proper belt tracking in conveyor systems. They are often utilized in conjunction with other pulleys, such as idler or snub pulleys, to guide the belt along the desired path. Tension pulleys help ensure that the belt remains aligned and centered on the conveyor, preventing it from wandering off track. Proper belt tracking minimizes belt wear, reduces the risk of damage to the conveyor structure, and improves overall system efficiency.

3. Load Distribution: Tension pulleys contribute to even load distribution across the conveyor belt. They help distribute the tension forces evenly along the belt, preventing localized stress concentrations. This balanced load distribution enhances belt life and minimizes the risk of premature failure or damage. Tension pulleys also ensure that the load is evenly transferred to the supporting structure, preventing excessive strain on specific components.

4. Tension Adjustment: Tension pulleys allow for easy tension adjustment in conveyor systems. Adjustable tension pulleys enable operators to fine-tune the belt tension based on the specific requirements of the material being conveyed. This flexibility ensures optimal tension for various load conditions, preventing excessive tension that can lead to belt damage or insufficient tension that can result in belt slippage. Tension adjustment also facilitates the accommodation of changes in material characteristics or system configurations.

5. Reduced Belt Wear: By maintaining proper tension, tension pulleys help reduce belt wear in material handling and conveyor systems. Insufficient tension can cause belt slippage, leading to accelerated wear and tear. Conversely, excessive tension can result in increased friction and premature belt wear. Tension pulleys ensure the right balance of tension, minimizing belt abrasion and extending belt life. Reduced belt wear translates to lower maintenance costs and improved system reliability.

6. Minimized Noise and Vibrations: Tension pulleys contribute to noise and vibration reduction in material handling and conveyor systems. Properly tensioned belts experience reduced vibrations and oscillations, resulting in quieter operation. The damping effect provided by tension pulleys helps minimize noise levels, creating a more comfortable and productive work environment. Reduced vibrations also contribute to improved system stability and longevity.

7. Improved Efficiency: Overall, tension pulleys enhance the efficiency of material handling and conveyor systems. By maintaining proper belt tension, they optimize power transfer, minimizing energy losses associated with slippage or excessive tension. Efficient power transmission results in improved system performance, reduced downtime, and enhanced productivity. Tension pulleys also contribute to smoother material flow, reducing the risk of jams or blockages that can disrupt operations.

In summary, tension pulleys offer several advantages in material handling and conveyor systems, including proper belt tension, belt tracking, load distribution, tension adjustment, reduced belt wear, minimized noise and vibrations, and improved system efficiency. Their role in maintaining optimal tension and facilitating smooth belt operation enhances the reliability, productivity, and longevity of material handling and conveyor systems.

What are some real-world examples of tension pulley systems in action?

Tension pulley systems are widely used in various real-world applications to achieve controlled movement, efficient power transmission, and tension regulation. Here are some examples of how tension pulley systems are employed in different industries and contexts:

1. Automotive Industry: Tension pulley systems are commonly found in automotive engines. They are utilized in the accessory belt drive systems to maintain proper tension and ensure efficient power transfer between the engine crankshaft and various accessories such as the alternator, power steering pump, and air conditioning compressor. Tension pulley systems in vehicles help minimize belt slippage, optimize accessory performance, and contribute to overall engine efficiency.

2. Printing Industry: In printing presses, tension pulley systems are utilized to control the tension of the printing web or paper. These systems maintain the appropriate tension throughout the printing process, ensuring accurate registration, preventing wrinkling or stretching of the paper, and enabling consistent ink transfer. Tension pulley systems play a crucial role in high-quality printing operations, such as newspaper printing or packaging production.

3. Textile Industry: Tension pulley systems are extensively utilized in textile manufacturing processes. In weaving machines, tension pulleys help regulate the tension of yarns during the weaving process, ensuring proper alignment, preventing thread breakage, and facilitating uniform fabric formation. Tension pulley systems are also employed in knitting machines to control the tension of yarns or threads, enabling precise stitch formation and enhancing the quality of knitted fabrics.

4. Fitness Equipment: Tension pulley systems are commonly incorporated into fitness equipment such as weightlifting machines or cable-based exercise systems. These systems use tension pulleys to guide and control the movement of cables, providing resistance for exercises. By adjusting the tension, users can customize the intensity of their workouts and target specific muscle groups. Tension pulley systems in fitness equipment offer versatile training options and enhance user experience.

5. Construction and Cranes: Tension pulley systems are employed in construction and crane applications to facilitate lifting and movement operations. For example, in tower cranes, tension pulley systems are used to guide and support the lifting cables, ensuring controlled movement of heavy loads. Tension pulley systems play a vital role in maintaining the stability and safety of lifting operations in construction sites and other industrial settings.

6. Material Handling and Conveyors: Tension pulley systems are integral components of material handling and conveyor systems across various industries. They are used to guide and tension belts, chains, or ropes, facilitating the movement of materials or products. Tension pulley systems in conveyors help regulate the tension and alignment of the conveyor belts, ensuring smooth and efficient material transfer in manufacturing, logistics, or warehouse environments.

7. Aerospace Industry: Tension pulley systems are utilized in aerospace applications, particularly in aircraft systems such as flight control systems or landing gear mechanisms. These systems use tension pulleys to control the tension and movement of cables or control surfaces, ensuring precise and responsive aircraft control. Tension pulley systems in aerospace contribute to the safety, reliability, and performance of aircraft operations.

These examples highlight the diverse range of applications where tension pulley systems are utilized in real-world scenarios. Whether in automotive engines, printing presses, textile manufacturing, fitness equipment, construction, material handling, or aerospace industry, tension pulley systems play a significant role in achieving controlled movement, efficient power transmission, and tension regulation in various mechanical systems.

Can you explain the key components and design features of a tension pulley?

A tension pulley, also known as an idler pulley or a belt tensioner, is a mechanical component used to maintain proper tension in belts or chains within a system. It consists of several key components and design features that enable its functionality. Here’s a detailed explanation of the key components and design features of a tension pulley:

1. Pulley Wheel: The pulley wheel is the main component of a tension pulley. It is a grooved wheel or sheave that guides the belt or chain and provides a contact surface for it to run on. The pulley wheel is typically made of durable materials such as steel or aluminum to withstand the forces and wear associated with tensioning and power transmission. The groove on the wheel is designed to match the profile of the belt or chain, ensuring proper engagement and minimizing slippage.

2. Shaft: The pulley wheel is mounted on a shaft, which allows it to rotate freely. The shaft is usually made of metal and is supported by bearings or bushings to reduce friction and enable smooth rotation. The shaft is connected to the pulley wheel either through a press fit, a keyway, or other secure means to ensure a reliable connection and transfer of rotational motion.

3. Tension Adjustment Mechanism: Tension pulleys feature a tension adjustment mechanism that allows for the control of belt or chain tension. The mechanism can vary depending on the design of the tension pulley. It may include components such as a bolt or screw, a spring-loaded arm, or a hydraulic or pneumatic actuator. These mechanisms enable the adjustment of the position or force applied by the tension pulley, allowing for precise tension control and maintenance.

4. Mounting Bracket or Arm: Tension pulleys are typically attached to a mounting bracket or arm, which provides support and allows for proper positioning within the system. The bracket or arm is often made of metal and may be adjustable to accommodate different belt or chain sizes or to facilitate tension adjustments. It is securely fastened to the system’s framework or structure to ensure stability and reliable operation.

5. Tensioner Spring: In some tension pulleys, particularly those with automatic tensioning mechanisms, a tensioner spring is used to provide the necessary force to maintain tension. The spring is typically coiled and mounted in a way that allows it to apply a constant force to the tension pulley. As the belt or chain stretches or wears, the tensioner spring compensates by exerting a force that keeps the tension within the desired range. This ensures consistent tension and reduces the need for manual adjustments.

6. Protective Covers or Shields: Depending on the application and environment, tension pulleys may feature protective covers or shields. These components help to protect the pulley wheel, shaft, bearings, and other internal parts from contaminants, debris, and potential damage. Protective covers or shields are commonly made of durable materials such as plastic or metal and are designed to be easily removable for maintenance and inspection purposes.

7. Additional Features: Some tension pulleys may include additional features to enhance their functionality or adapt to specific system requirements. These features can include belt or chain guides to ensure proper alignment, integrated bearings for smooth operation, belt or chain tension indicators for visual monitoring, or even specialized coatings or treatments to enhance durability and reduce friction.

In summary, a tension pulley is composed of key components such as the pulley wheel, shaft, tension adjustment mechanism, mounting bracket or arm, tensioner spring (in some cases), protective covers or shields, and additional features as required. The design features of a tension pulley are carefully engineered to provide reliable tension control, proper engagement with belts or chains, and longevity in various mechanical systems.

editor by CX

2024-01-24