Product Description

Product Description

1.Teeth Profile:

|

HTD: |

3M,5M,8M,14M,20M |

|||

|

T&AT: |

T2.5,T5,T10, AT5,AT10,AT20 |

|||

|

STPD: |

S2M,S3M,S4.5M,S5M,S8M,S14M |

|||

|

RPP: |

5M,8M,14M,20M |

|||

|

PGGT (PowerGrip GT): |

2MR,3MR,5MR,8MR,14MR |

|||

2. Materials:

Aluminum timing pulleys

Characteristics:

1.suitable for moderate power transmission

2.light weight / reduced rotational inertia

3.moderate chemical and corrosion resistance

4.standard material for stock pulleys

Steel timing pulleys

Characteristics:

1.suitable for high power transmission

2.durable

3.limited chemical and corrosion resistance

4.aesthetic material

3.Surface Finishes:

Anodize Treatment

-used on aluminum pulleys

Characteristics:

1. Increased chemical and corrosion resistance

2. Available in natural, black, or colored

3. Limited increase of surface hardness

4. Aesthetic treatment

Black Oxide

– used on steel pulleys

Characteristics:

1. Increased chemical and corrosion resistance

2. Aesthetic treatment

Packaging & Shipping

Test

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd.

1. Was founded in 2008

2. Our Principle:

“Credibility Supremacy, and Customer First”

3. Our Promise:

“High quality products, and Excellent Service”

4. Our Value:

“Being Honesty, Doing the Best, and Long-lasting Development”

5. Our Aim:

“Develop to be a leader in the power transmission parts industry in the world”

|

6.Our services: |

1).Competitive price |

|||

|

2).High quality products |

||||

|

3).OEM service or can customized according to your drawings |

||||

|

4).Reply your inquiry in 24 hours |

||||

|

5).Professional technical team 24 hours online service |

||||

|

6).Provide sample service |

||||

Main products

Machines

Exbihition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Manufacturing Process: | Hobbing |

|---|---|

| Material: | Carbon Steel |

| Surface Treatment: | Polishing |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Pitch for Arc Tooth: | 3mm/5mm/8mm/14mm/20mm |

| Pitch for T Tooth: | 2mm/5mm/10mm/20mm |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How are tension pulleys integrated into HVAC systems and air conditioning units?

Tension pulleys play a crucial role in HVAC (Heating, Ventilation, and Air Conditioning) systems and air conditioning units by ensuring proper tension and alignment of belts that drive various components. Here is a detailed explanation of how tension pulleys are integrated into these systems:

In HVAC systems and air conditioning units, tension pulleys are primarily used in belt-driven applications, where a motor drives a belt that transfers power to different components, such as fans, blowers, compressors, and pumps. The tension pulleys help maintain the correct tension in the belts, ensuring efficient power transmission and preventing slippage or excessive wear.

The integration of tension pulleys into HVAC systems and air conditioning units involves the following steps:

1. Belt Selection: The appropriate type and size of belts are selected based on the power requirements, speed, and the components being driven. Factors such as load, temperature, and environmental conditions are considered during belt selection. The belts should be compatible with the tension pulleys and provide the necessary grip and flexibility for efficient power transmission.

2. Pulley Placement: The tension pulleys are strategically placed within the system to guide and tension the belts. They are typically positioned at the points where the belt changes direction or wraps around a component. The precise placement depends on the specific system design and the location of the driven components.

3. Pulley Configuration: The tension pulleys are configured to match the belt profile and size. Pulleys with the appropriate diameter, width, and groove profile are selected to ensure proper belt engagement and alignment. The pulley configuration is optimized to minimize belt slippage, reduce noise, and maximize power transfer efficiency.

4. Tension Adjustment: The tension pulleys are designed to be adjustable, allowing for proper tensioning of the belts. The tension can be adjusted by either changing the position of the pulley or applying tensioning mechanisms such as spring-loaded arms or hydraulic systems. Proper tension adjustment is crucial for optimal performance and longevity of the belts and driven components.

5. Maintenance and Inspection: Regular maintenance and inspection of the tension pulleys and belts are essential to ensure their proper function. This includes checking for signs of wear, misalignment, or belt damage. The tension pulleys should be lubricated, if required, and any issues should be promptly addressed to prevent belt failure or system downtime.

6. Belt Replacement: Over time, belts may wear out or become damaged. When replacing belts in HVAC systems and air conditioning units, it is important to ensure that the new belts are compatible with the existing tension pulleys. The tension pulleys may need to be adjusted to accommodate the new belt length or thickness.

Overall, tension pulleys are integral components in HVAC systems and air conditioning units that help maintain proper belt tension and alignment. By ensuring efficient power transmission, they contribute to the reliable and smooth operation of the driven components, enhancing the overall performance and energy efficiency of the system.

What are some real-world examples of tension pulley systems in action?

Tension pulley systems are widely used in various real-world applications to achieve controlled movement, efficient power transmission, and tension regulation. Here are some examples of how tension pulley systems are employed in different industries and contexts:

1. Automotive Industry: Tension pulley systems are commonly found in automotive engines. They are utilized in the accessory belt drive systems to maintain proper tension and ensure efficient power transfer between the engine crankshaft and various accessories such as the alternator, power steering pump, and air conditioning compressor. Tension pulley systems in vehicles help minimize belt slippage, optimize accessory performance, and contribute to overall engine efficiency.

2. Printing Industry: In printing presses, tension pulley systems are utilized to control the tension of the printing web or paper. These systems maintain the appropriate tension throughout the printing process, ensuring accurate registration, preventing wrinkling or stretching of the paper, and enabling consistent ink transfer. Tension pulley systems play a crucial role in high-quality printing operations, such as newspaper printing or packaging production.

3. Textile Industry: Tension pulley systems are extensively utilized in textile manufacturing processes. In weaving machines, tension pulleys help regulate the tension of yarns during the weaving process, ensuring proper alignment, preventing thread breakage, and facilitating uniform fabric formation. Tension pulley systems are also employed in knitting machines to control the tension of yarns or threads, enabling precise stitch formation and enhancing the quality of knitted fabrics.

4. Fitness Equipment: Tension pulley systems are commonly incorporated into fitness equipment such as weightlifting machines or cable-based exercise systems. These systems use tension pulleys to guide and control the movement of cables, providing resistance for exercises. By adjusting the tension, users can customize the intensity of their workouts and target specific muscle groups. Tension pulley systems in fitness equipment offer versatile training options and enhance user experience.

5. Construction and Cranes: Tension pulley systems are employed in construction and crane applications to facilitate lifting and movement operations. For example, in tower cranes, tension pulley systems are used to guide and support the lifting cables, ensuring controlled movement of heavy loads. Tension pulley systems play a vital role in maintaining the stability and safety of lifting operations in construction sites and other industrial settings.

6. Material Handling and Conveyors: Tension pulley systems are integral components of material handling and conveyor systems across various industries. They are used to guide and tension belts, chains, or ropes, facilitating the movement of materials or products. Tension pulley systems in conveyors help regulate the tension and alignment of the conveyor belts, ensuring smooth and efficient material transfer in manufacturing, logistics, or warehouse environments.

7. Aerospace Industry: Tension pulley systems are utilized in aerospace applications, particularly in aircraft systems such as flight control systems or landing gear mechanisms. These systems use tension pulleys to control the tension and movement of cables or control surfaces, ensuring precise and responsive aircraft control. Tension pulley systems in aerospace contribute to the safety, reliability, and performance of aircraft operations.

These examples highlight the diverse range of applications where tension pulley systems are utilized in real-world scenarios. Whether in automotive engines, printing presses, textile manufacturing, fitness equipment, construction, material handling, or aerospace industry, tension pulley systems play a significant role in achieving controlled movement, efficient power transmission, and tension regulation in various mechanical systems.

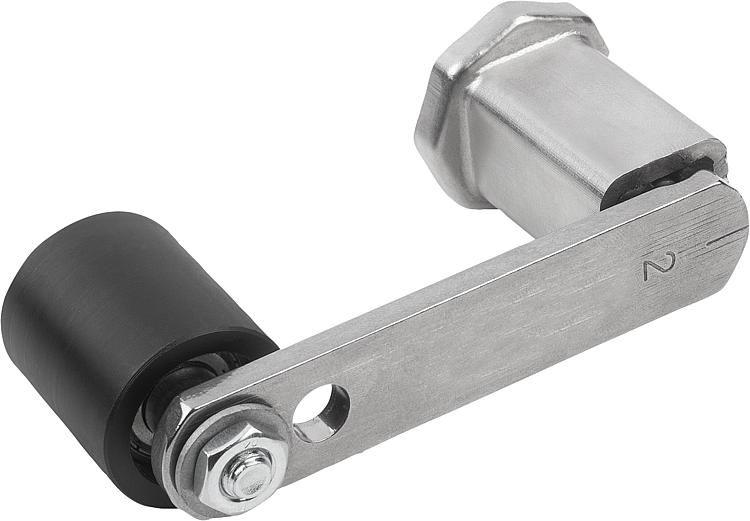

Can you explain the key components and design features of a tension pulley?

A tension pulley, also known as an idler pulley or a belt tensioner, is a mechanical component used to maintain proper tension in belts or chains within a system. It consists of several key components and design features that enable its functionality. Here’s a detailed explanation of the key components and design features of a tension pulley:

1. Pulley Wheel: The pulley wheel is the main component of a tension pulley. It is a grooved wheel or sheave that guides the belt or chain and provides a contact surface for it to run on. The pulley wheel is typically made of durable materials such as steel or aluminum to withstand the forces and wear associated with tensioning and power transmission. The groove on the wheel is designed to match the profile of the belt or chain, ensuring proper engagement and minimizing slippage.

2. Shaft: The pulley wheel is mounted on a shaft, which allows it to rotate freely. The shaft is usually made of metal and is supported by bearings or bushings to reduce friction and enable smooth rotation. The shaft is connected to the pulley wheel either through a press fit, a keyway, or other secure means to ensure a reliable connection and transfer of rotational motion.

3. Tension Adjustment Mechanism: Tension pulleys feature a tension adjustment mechanism that allows for the control of belt or chain tension. The mechanism can vary depending on the design of the tension pulley. It may include components such as a bolt or screw, a spring-loaded arm, or a hydraulic or pneumatic actuator. These mechanisms enable the adjustment of the position or force applied by the tension pulley, allowing for precise tension control and maintenance.

4. Mounting Bracket or Arm: Tension pulleys are typically attached to a mounting bracket or arm, which provides support and allows for proper positioning within the system. The bracket or arm is often made of metal and may be adjustable to accommodate different belt or chain sizes or to facilitate tension adjustments. It is securely fastened to the system’s framework or structure to ensure stability and reliable operation.

5. Tensioner Spring: In some tension pulleys, particularly those with automatic tensioning mechanisms, a tensioner spring is used to provide the necessary force to maintain tension. The spring is typically coiled and mounted in a way that allows it to apply a constant force to the tension pulley. As the belt or chain stretches or wears, the tensioner spring compensates by exerting a force that keeps the tension within the desired range. This ensures consistent tension and reduces the need for manual adjustments.

6. Protective Covers or Shields: Depending on the application and environment, tension pulleys may feature protective covers or shields. These components help to protect the pulley wheel, shaft, bearings, and other internal parts from contaminants, debris, and potential damage. Protective covers or shields are commonly made of durable materials such as plastic or metal and are designed to be easily removable for maintenance and inspection purposes.

7. Additional Features: Some tension pulleys may include additional features to enhance their functionality or adapt to specific system requirements. These features can include belt or chain guides to ensure proper alignment, integrated bearings for smooth operation, belt or chain tension indicators for visual monitoring, or even specialized coatings or treatments to enhance durability and reduce friction.

In summary, a tension pulley is composed of key components such as the pulley wheel, shaft, tension adjustment mechanism, mounting bracket or arm, tensioner spring (in some cases), protective covers or shields, and additional features as required. The design features of a tension pulley are carefully engineered to provide reliable tension control, proper engagement with belts or chains, and longevity in various mechanical systems.

editor by CX

2024-03-14