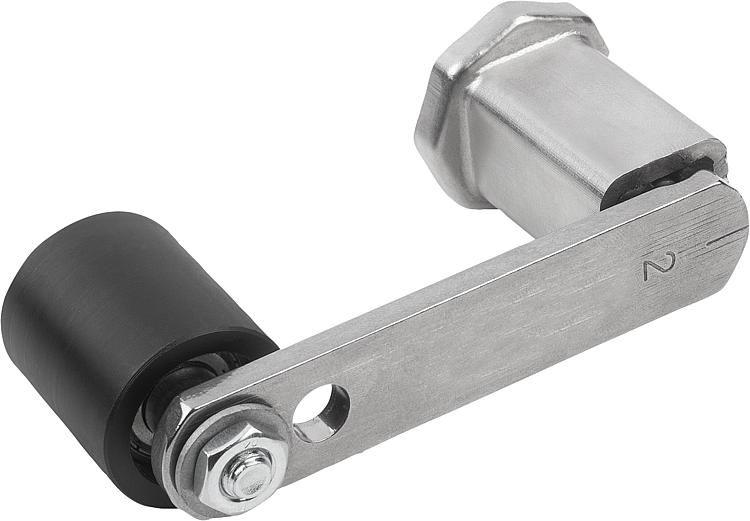

Product Description

Deep groove ball bearing

| NSK | A | B | C | D | D2 | S2 | |||

| WN2358-1S | 3.59 | 0.53 | 1.53 | 0.6267 | 0.4739 | 1.44 | |||

| WN2364-7S | 3.64 | 0.59 | 1.52 | 0.6267 | 0.4739 | 1.43 | |||

| WN2375-4S | 3.76 | 0.56 | 1.67 | 0.6267 | 0.4739 | 1.59 | |||

| WN2388-2S | 3.89 | 0.73 | 1.63 | 0.6267 | 0.4739 | 1.55 | |||

| 665331 | WN2397S | 3.98 | 0.98 | 1.46 | 0.6267 | 0.4739 | 1.36 | ||

| WN2405S | 4.06 | 0.65 | 1.88 | 0.6267 | 0.4739 | 1.79 | |||

| WN2413-2S | 4.13 | 1.21 | 1.39 | 0.6267 | 0.4739 | 1.26 | |||

| WN2419S | 4.19 | 0.87 | 1.8 | 0.6267 | 0.4739 | 1.72 | |||

| WN2434-4S | 4.35 | 0.84 | 1.97 | 0.6267 | 0.4739 | 1.9 | |||

| WN2461-1S | 4.62 | 0.72 | 2.37 | 0.6267 | 0.4739 | 2.29 | |||

| WN2479S | 4.8 | 1.24 | 2.03 | 0.6267 | 0.4739 | 1.95 | |||

| WN3399-2S | 4 | 0.69 | 1.78 | 0.6275 | 0.4739 | 1.7 | |||

| WN63975 | 3.98 | 0.98 | 1.46 | 0.62 | 0.4744 | 1.36 | |||

| NSK | A | B | C | D | |||||

| 885154 | W2289 | 2.89 | 0.16 | 1.2 | 0.6267 | ||||

| 885165 | W2325 | 3.25 | 0.16 | 1.56 | 0.6267 | ||||

| W2325-3 | 3.55 | 0.67 | 1.35 | 0.6267 | |||||

| 885330 | W2366 | 3.66 | 0.73 | 1.4 | 0.6267 | ||||

| W2371 | 3.71 | 0.69 | 1.5 | 0.6267 | |||||

| W2375-3 | 3.76 | 0.56 | 1.67 | 0.6267 | |||||

| w-s series | |||||||||

| NSK | A | B | C | D | D1 | S1 | D2 | S2 | |

| 885122 | W2334S | 3.35 | 0.51 | 1.3 | 0.6267 | 0.4739 | 1.18 | ||

| W2346-1S | 3.47 | 0.49 | 1.45 | 0.6267 | 0.4739 | 1.33 | |||

| W2346-2S | 3.47 | 0.56 | 1.38 | 0.6267 | 0.4739 | 1.28 | |||

| W2355S | 3.55 | 0.61 | 1.41 | 0.6267 | 0.4739 | 1.33 | |||

| W2364-5S | 3.64 | 0.65 | 1.46 | 0.6267 | 0.4739 | 1.36 | |||

| 885477 | W2364S | 3.64 | 0.99 | 1.12 | 0.6267 | 0.4739 | 1.02 | ||

| W2366-1S | 3.66 | 0.65 | 1.49 | 0.6267 | 0.4739 | 1.33 | |||

| wn series | |||||||||

| NSK | A | B | C | D | |||||

| WN2269 | 2.69 | 0.99 | 0.18 | 0.6267 | |||||

| WN2366-4 | 3.66 | 0.73 | 1.4 | 0.6267 | |||||

| 665343 | WN2375-3 | 3.76 | 0.56 | 1.67 | 0.6267 | ||||

| WN2401-5 | 4.02 | 0.67 | 1.82 | 0.6267 | |||||

| WN2410 | 4.1 | 1.03 | 1.54 | 0.6267 | |||||

| 665329 | WN2415-1 | 4.15 | 0.8 | 1.82 | 0.6267 | ||||

| WN2434 | 4.35 | 0.84 | 1.97 | 0.6267 | |||||

| WN2447 | 4.48 | 1.42 | 1.52 | 0.6267 | |||||

| WN2488-1 | 4.49 | 0.75 | 2.21 | 0.6267 | |||||

| WN2450-2 | 4.5 | 1.26 | 1.71 | 0.6267 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Water Pump Bearing |

|---|---|

| The Number of Rows: | Single |

| Material: | Bearing Steel |

| Load Direction: | Radial Bearing |

| Separated: | Separated |

| Trademark: | OEM |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when using tension pulleys?

When using tension pulleys, it is crucial to prioritize safety to prevent accidents and ensure the well-being of personnel. Here are some important safety considerations to keep in mind:

1. Proper Guarding: Tension pulleys should be adequately guarded to prevent accidental contact with moving parts. Guards should be designed and installed in accordance with applicable safety standards and regulations. They should be securely attached and provide sufficient coverage to prevent access to the pulley and associated belts, reducing the risk of entanglement or injury.

2. Lockout/Tagout Procedures: Before performing any maintenance or repair tasks on machinery or equipment with tension pulleys, proper lockout/tagout procedures should be followed. This involves isolating the power source, de-energizing the system, and securing it with locks or tags to prevent accidental startup. Lockout/tagout procedures help protect personnel from unexpected movement or energization of the pulleys during maintenance activities.

3. Training and Awareness: Adequate training should be provided to personnel involved in the operation, maintenance, and servicing of machinery with tension pulleys. They should be educated about the potential hazards associated with tension pulleys, such as entanglement, pinch points, and rotating parts. Training should cover safe work practices, proper use of personal protective equipment (PPE), and emergency procedures. Regular safety reminders and refresher training sessions are also beneficial to maintain awareness and reinforce safe behaviors.

4. Proper Use of Personal Protective Equipment (PPE): Depending on the specific hazards present, appropriate personal protective equipment should be worn by personnel working with tension pulleys. This may include safety glasses, gloves, hearing protection, and, if necessary, respiratory protection. PPE helps protect against potential injuries from flying debris, contact with moving parts, and exposure to noise or airborne contaminants.

5. Maintaining Proper Belt Tension: It is important to maintain proper belt tension within the recommended range specified by the manufacturer. Insufficient tension can result in belt slippage, while excessive tension can overload the system and lead to premature wear or failure. Regular inspections and adjustments should be performed to ensure the tension is within the specified limits. This helps maintain safe and efficient operation of the tension pulleys and associated equipment.

6. Regular Inspection and Maintenance: Tension pulleys should be regularly inspected for signs of wear, damage, or misalignment. Any issues should be promptly addressed to prevent potential hazards. Routine maintenance, such as cleaning, lubrication, and replacement of worn components, should be carried out as per the manufacturer’s recommendations. Regular inspections and maintenance help identify and rectify potential safety concerns before they escalate.

7. Proper Lifting and Handling: When handling tension pulleys or performing maintenance tasks, proper lifting techniques and equipment should be used to prevent strains or injuries. Pulleys can be heavy and awkward to handle, so mechanical lifting aids or assistance from trained personnel may be necessary. Adequate precautions should be taken to prevent pulleys from falling or rolling during transportation or installation.

8. Clear Communication and Signage: Clear communication and proper signage should be in place to indicate the presence of tension pulleys and associated hazards. Warning signs, labels, or color-coded markings can help alert personnel to potential dangers and remind them of safety precautions. Safety instructions, including emergency contact information, should be prominently displayed in the vicinity of tension pulleys.

9. Regular Risk Assessments: Conducting regular risk assessments specific to the machinery and equipment using tension pulleys is essential. This helps identify potential hazards, assess their severity and likelihood, and implement appropriate control measures. Risk assessments should be reviewed periodically and updated as necessary to account for changes in equipment, processes, or operating conditions.

By adhering to these safety considerations, the risks associated with tension pulleys can be minimized, creating a safer working environment for personnel and reducing the likelihood of accidents or injuries.

How are tension pulleys used in the production of electronics and semiconductors?

Tension pulleys play a crucial role in the production of electronics and semiconductors, particularly in manufacturing processes that involve precision and delicate handling of materials. They are utilized in various stages of production to ensure accurate positioning, controlled movement, and proper tensioning of components and materials. Here’s a detailed explanation of how tension pulleys are used in the production of electronics and semiconductors:

1. Material Handling: Tension pulleys are often used in the material handling processes during the production of electronics and semiconductors. They are employed in conveyor systems to guide and tension delicate materials such as thin films, wafers, and flexible circuit boards. Tension pulleys help ensure smooth and controlled movement of these materials, minimizing the risk of damage or misalignment during transportation between different production stages.

2. Web Processing: In the production of electronic components such as printed circuit boards (PCBs) or flexible displays, tension pulleys are utilized in web processing systems. These systems handle continuous rolls of materials, such as films, foils, or substrates, and involve processes like coating, laminating, or die-cutting. Tension pulleys are critical in maintaining the proper tension of the web as it moves through various processing stations, ensuring precise alignment and consistent quality of the produced components.

3. Wire and Cable Manufacturing: Tension pulleys are extensively used in the manufacturing of wires and cables for electronic applications. They are employed in wire drawing machines and cable extrusion lines to maintain consistent tension on the wire or cable being produced. Tension pulleys help control the speed and tension of the wire or cable, ensuring uniform diameter, proper insulation, and reliable electrical properties throughout the manufacturing process.

4. Component Assembly: Tension pulleys are integrated into assembly systems for the precise positioning and alignment of electronic components. For example, in surface mount technology (SMT) processes, tension pulleys are utilized in pick-and-place machines to guide and tension the reels of surface mount devices (SMDs) as they are accurately placed onto PCBs. Tension pulleys play a crucial role in ensuring the controlled movement and accurate placement of components, contributing to the overall quality and reliability of electronic assemblies.

5. Wafer Processing: In semiconductor manufacturing, tension pulleys are employed in wafer processing equipment. They are used in systems such as chemical mechanical planarization (CMP) or wafer dicing machines. Tension pulleys help control the tension and movement of the wafers during processes like polishing, grinding, or dicing, ensuring precise material removal, accurate alignment, and minimizing the risk of wafer breakage or damage.

It is important to note that tension pulleys used in the production of electronics and semiconductors are often designed with precision and controlled motion in mind. They are typically made from materials that minimize particle generation or contamination and incorporate features such as low friction bearings or special coatings to ensure smooth operation without compromising the cleanliness of the production environment.

In summary, tension pulleys are extensively utilized in the production of electronics and semiconductors. They contribute to accurate material handling, controlled movement, and precise positioning of components and materials, ultimately enhancing the quality, reliability, and efficiency of the manufacturing processes in the electronics and semiconductor industry.

How do tension pulleys help maintain proper belt or cable tension?

Tension pulleys play a critical role in maintaining proper tension in belts or cables within mechanical systems. They are designed to apply the necessary force to keep the belt or cable taut and properly engaged with the pulleys or sheaves. Here’s a detailed explanation of how tension pulleys help maintain proper belt or cable tension:

Tension pulleys are typically placed in the path of the belt or cable and are adjustable to exert the desired amount of tension. They can be fixed in position or spring-loaded to automatically adjust the tension as needed. The specific method of tension adjustment may vary depending on the design and application of the system.

Here are the key mechanisms through which tension pulleys help maintain proper belt or cable tension:

- Tension Regulation: Tension pulleys allow for precise regulation of belt or cable tension. By adjusting the position or force of the tension pulley, the tension in the belt or cable can be increased or decreased. This adjustability is crucial during system installation, maintenance, or when the belt or cable stretches or wears over time. By fine-tuning the tension, the tension pulley ensures that the belt or cable remains properly tensioned for optimal performance.

- Preventing Slack: Tension pulleys prevent slack or excessive looseness in belts or cables. When there is insufficient tension, belts or cables can become loose and lose their grip on the pulleys or sheaves. This can lead to slippage, reduced power transmission, and even disengagement from the system. Tension pulleys apply the necessary force to eliminate slack and maintain a tight, secure grip, ensuring effective power transfer and smooth operation.

- Compensating for Stretching: Over time, belts or cables may stretch due to continuous operation or exposure to loads. Tension pulleys help compensate for this stretching by providing an adjustable tensioning element. As the belt or cable stretches, the tension pulley can be adjusted to increase the tension and restore the proper tension level. This ensures that the belt or cable remains taut and maintains its intended functionality and performance.

- Ensuring Proper Engagement: Proper tension in belts or cables is vital for their engagement with pulleys or sheaves. Insufficient tension can cause the belt or cable to slip or disengage from the pulleys, resulting in a loss of power transmission and functionality. Tension pulleys apply the necessary force to keep the belt or cable properly engaged, ensuring reliable power transfer and preventing interruptions or failures in the system.

- Maintaining Consistent Tension: Tension pulleys help maintain a consistent tension in belts or cables under varying operating conditions. Changes in load, temperature, or other factors can affect the tension requirements of the system. Tension pulleys with automatic tensioning mechanisms, such as springs, can adapt to these variations and automatically adjust the tension to keep it within the desired range. This ensures that the belt or cable remains properly tensioned and optimally operational throughout the system’s operation.

In summary, tension pulleys are crucial for maintaining proper tension in belts or cables within mechanical systems. They regulate tension, prevent slack, compensate for stretching, ensure proper engagement, and maintain consistent tension. By fulfilling these functions, tension pulleys contribute to the reliable and efficient operation of various systems, including conveyor belts, cable-driven mechanisms, power transmission systems, and more.

editor by CX

2024-04-23