Product Description

Product Description

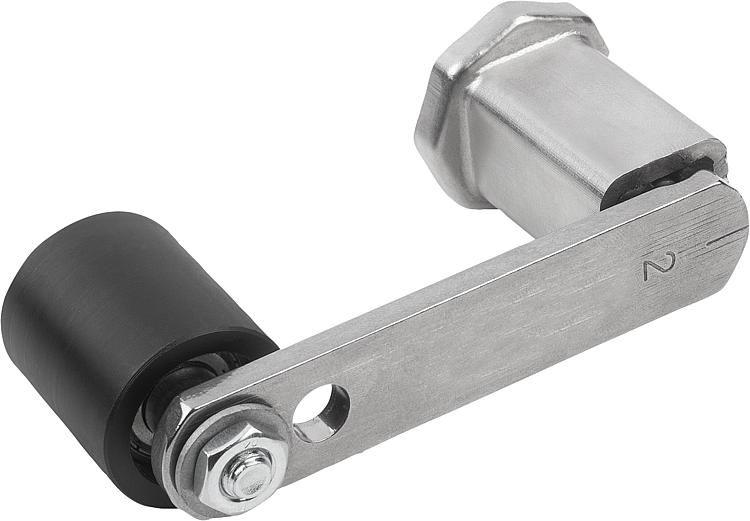

| Original CHINAMFG CHINAMFG manufacturer Automatic Tension Pulley VG260006571 | |||

| Type | Automatic Tension Pulley | Application | heavy truck |

| Truck model | howo | Certification | ISO9001 |

| OEM number | VG260006571 | Warranty | 12 months |

| Item Name | Automatic Tension Pulley | Packing | standard |

| Place of origin | ZheJiang provice, china | MOQ | 1 Piece |

| Brand name | sinotruk | Qulity | OEM original |

| Adaptable automobile mode: | SINOTRUK | Payment | TT, western union, L/C, paypal, etc. |

Products

Company Profile

Belt Way International Trading Co.,Ltd. was founded in 2008. Specializing in the production and sales of various auto parts. With the spirit of continuous innovation and excellent technical concept, Beltway focuses on the development and improvement of products, and is committed to providing the best quality products to meet the various needs of customers.

Our factory

Exhibition

Packing & Delivery

FAQ

1. Q: Are you a manufacturer or trading company?

A: We are manufacturer.

2. Q: What about your products quality?

A:”Quality is priority.” We always attach great importance to quality controlling from the very beginning.

3.Q:What payment do you accept?

A: T/T, L/C, Trade assurance;

4.Q:What is the MOQ of your products?

A: 1 set. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Engine |

|---|---|

| Certification: | ISO9001 |

| Driving System Parts: | Frame |

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can tension pulleys be customized for specific machinery and equipment?

Yes, tension pulleys can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation of the customization possibilities for tension pulleys:

Tension pulleys are vital components in various industrial applications, and their design and specifications can be tailored to meet the specific needs of different machinery and equipment. Customization allows for a precise fit and optimal performance in the given application. Here are some aspects that can be customized:

1. Size and Dimensions: Tension pulleys can be customized in terms of their size and dimensions to ensure compatibility with the specific machinery and equipment. This includes the diameter, width, and hub dimensions of the pulley. Customizing the size ensures that the tension pulley fits properly within the available space and aligns correctly with the conveyor system or other components.

2. Pulley Profile: The profile of a tension pulley can be customized to match the requirements of the machinery and the type of belt being used. Different profiles, such as flat, crowned, or v-shaped, can be chosen based on the desired belt tracking and tension distribution. Customizing the pulley profile helps optimize belt alignment, reduce wear, and ensure efficient power transmission.

3. Material Selection: Tension pulleys can be customized in terms of the material used for their construction. The material selection depends on factors such as the application environment, load requirements, and chemical or temperature resistance. Common materials for tension pulleys include steel, cast iron, aluminum, and various engineering plastics. Customizing the material ensures that the pulley has the necessary strength, durability, and resistance to meet the specific operating conditions.

4. Bearing Type and Specifications: Tension pulleys can be customized with different types and specifications of bearings to suit the specific machinery and equipment. The choice of bearings depends on factors such as load capacity, rotational speed, and maintenance requirements. Customizing the bearing type and specifications ensures smooth rotation, reduces friction, and enhances the overall performance and reliability of the tension pulley.

5. Surface Coatings and Finishes: Tension pulleys can be customized with surface coatings or finishes to enhance their performance in specific applications. For example, pulleys used in corrosive environments may be coated with materials that provide resistance to chemicals or moisture. Additionally, pulleys can be finished with smooth or textured surfaces depending on the desired frictional characteristics and grip.

6. Attachment and Mounting Options: Customization of tension pulleys can include different attachment and mounting options to ensure compatibility with the machinery and equipment. This may involve custom shaft sizes, keyway configurations, or specific mounting brackets. Customizing the attachment and mounting options facilitates easy installation and integration of the tension pulley into the existing system.

7. Additional Features: Depending on the specific requirements, tension pulleys can be customized with additional features or components. This can include dust or debris guards, specialized belt guides, or sensors for belt tracking or tension monitoring. Customization allows for the incorporation of features that enhance the functionality, safety, and efficiency of the tension pulley in the particular machinery or equipment.

By offering customization options, manufacturers can provide tension pulleys that precisely match the needs of specific machinery and equipment. Customized tension pulleys ensure optimal performance, longevity, and reliability in material handling and conveyor systems, thereby contributing to efficient and smooth operations.

How are tension pulleys used in the production of electronics and semiconductors?

Tension pulleys play a crucial role in the production of electronics and semiconductors, particularly in manufacturing processes that involve precision and delicate handling of materials. They are utilized in various stages of production to ensure accurate positioning, controlled movement, and proper tensioning of components and materials. Here’s a detailed explanation of how tension pulleys are used in the production of electronics and semiconductors:

1. Material Handling: Tension pulleys are often used in the material handling processes during the production of electronics and semiconductors. They are employed in conveyor systems to guide and tension delicate materials such as thin films, wafers, and flexible circuit boards. Tension pulleys help ensure smooth and controlled movement of these materials, minimizing the risk of damage or misalignment during transportation between different production stages.

2. Web Processing: In the production of electronic components such as printed circuit boards (PCBs) or flexible displays, tension pulleys are utilized in web processing systems. These systems handle continuous rolls of materials, such as films, foils, or substrates, and involve processes like coating, laminating, or die-cutting. Tension pulleys are critical in maintaining the proper tension of the web as it moves through various processing stations, ensuring precise alignment and consistent quality of the produced components.

3. Wire and Cable Manufacturing: Tension pulleys are extensively used in the manufacturing of wires and cables for electronic applications. They are employed in wire drawing machines and cable extrusion lines to maintain consistent tension on the wire or cable being produced. Tension pulleys help control the speed and tension of the wire or cable, ensuring uniform diameter, proper insulation, and reliable electrical properties throughout the manufacturing process.

4. Component Assembly: Tension pulleys are integrated into assembly systems for the precise positioning and alignment of electronic components. For example, in surface mount technology (SMT) processes, tension pulleys are utilized in pick-and-place machines to guide and tension the reels of surface mount devices (SMDs) as they are accurately placed onto PCBs. Tension pulleys play a crucial role in ensuring the controlled movement and accurate placement of components, contributing to the overall quality and reliability of electronic assemblies.

5. Wafer Processing: In semiconductor manufacturing, tension pulleys are employed in wafer processing equipment. They are used in systems such as chemical mechanical planarization (CMP) or wafer dicing machines. Tension pulleys help control the tension and movement of the wafers during processes like polishing, grinding, or dicing, ensuring precise material removal, accurate alignment, and minimizing the risk of wafer breakage or damage.

It is important to note that tension pulleys used in the production of electronics and semiconductors are often designed with precision and controlled motion in mind. They are typically made from materials that minimize particle generation or contamination and incorporate features such as low friction bearings or special coatings to ensure smooth operation without compromising the cleanliness of the production environment.

In summary, tension pulleys are extensively utilized in the production of electronics and semiconductors. They contribute to accurate material handling, controlled movement, and precise positioning of components and materials, ultimately enhancing the quality, reliability, and efficiency of the manufacturing processes in the electronics and semiconductor industry.

How do tension pulleys contribute to efficient power transmission?

Tension pulleys play a crucial role in ensuring efficient power transmission in mechanical systems. By maintaining proper tension in belts or chains, tension pulleys enable smooth and reliable transfer of power from the driving source to the driven components. Here’s a detailed explanation of how tension pulleys contribute to efficient power transmission:

1. Preventing Slippage: Tension pulleys help prevent belt or chain slippage, which can occur when there is insufficient tension. Slippage leads to a loss of power transmission efficiency as the rotational force fails to transfer effectively. Tension pulleys maintain optimal tension, maximizing the contact between the belt or chain and the pulley, thereby minimizing slippage and ensuring efficient power transfer.

2. Reducing Vibrations and Noise: Proper tensioning of belts or chains using tension pulleys helps reduce vibrations and noise in the power transmission system. When the tension is too low, the belt or chain may oscillate or produce excessive vibrations, leading to energy losses and increased noise levels. Tension pulleys maintain stable belt or chain tension, minimizing vibrations and noise, and enhancing power transmission efficiency.

3. Optimizing Power Transfer: Tension pulleys enable optimal power transfer by maintaining the desired tension in belts or chains. Adequate tension ensures that the force applied to the belt or chain is efficiently transmitted to the driven components, such as pumps, compressors, or generators. By optimizing power transfer, tension pulleys contribute to efficient operation and performance of the entire system.

4. Compensating for Belt or Chain Stretch: Over time, belts or chains can experience elongation or stretch due to wear or thermal effects. Tension pulleys are designed to compensate for this stretch by providing adjustable tension. They allow for tension adjustment to accommodate the elongation of belts or chains, ensuring consistent and efficient power transmission despite the stretching effect.

5. Facilitating Belt or Chain Engagement: Tension pulleys ensure proper engagement between the belt or chain and the pulley system. By applying tension, they ensure that the belt or chain remains securely in the pulley’s grooves or teeth, preventing disengagement or skipping. Secure engagement enhances power transmission efficiency by minimizing energy losses and maintaining a continuous and reliable transfer of power.

6. Adapting to Variable Load Conditions: Tension pulleys are designed to adapt to variable load conditions in power transmission systems. As the load changes, the tension pulleys can automatically adjust the tension in the belts or chains to compensate for the variations. This adaptability helps maintain optimal tension levels for efficient power transmission, regardless of the load fluctuations.

7. Extending Belt or Chain Life: By maintaining proper tension, tension pulleys help extend the life of belts or chains used in power transmission. Insufficient tension can cause premature wear and fatigue, leading to belt or chain failure. Conversely, excessive tension can lead to increased stress and accelerated wear. Tension pulleys ensure the right balance of tension, promoting longevity and reliability of the belts or chains, thus contributing to efficient power transmission over an extended period.

In summary, tension pulleys contribute to efficient power transmission by preventing slippage, reducing vibrations and noise, optimizing power transfer, compensating for belt or chain stretch, facilitating belt or chain engagement, adapting to variable load conditions, and extending the life of belts or chains. Their role in maintaining proper tension ensures smooth and reliable power transfer, maximizing the efficiency and performance of mechanical systems.

editor by CX

2024-04-03